Duct Leakage Testing Services Overview

Visitors can learn about duct leakage testing services and compare local contractors who perform this work.

- - Residential homeowners seeking to improve indoor comfort and energy efficiency through duct sealing.

- - Commercial property managers aiming to identify and address duct leakage issues in large or complex building systems.

- - HVAC professionals and contractors looking for reliable leads to connect with clients needing duct leakage testing services.

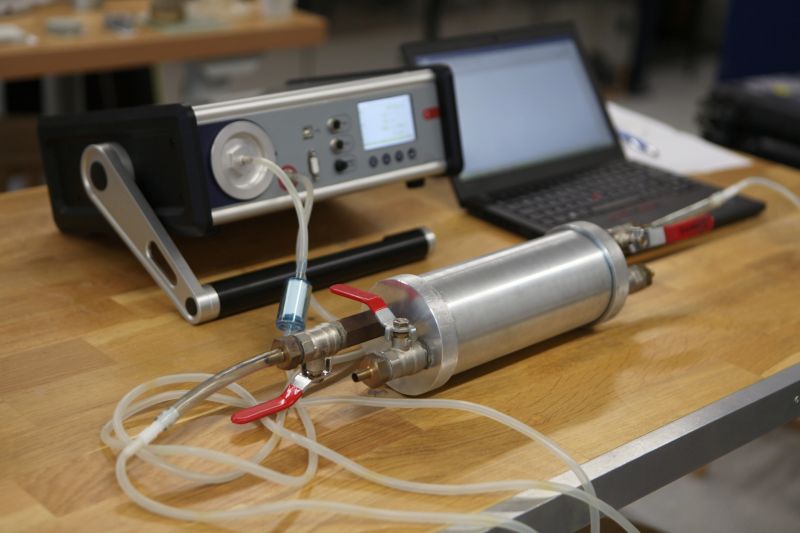

Duct leakage testing services are essential for property owners seeking to assess the integrity of their HVAC duct systems. These tests help identify areas where conditioned air may be escaping, which can impact energy efficiency and indoor comfort. When searching for duct leakage testing, property owners typically look for experienced local contractors who have the proper equipment and expertise to perform accurate assessments. These professionals evaluate ductwork in residential and commercial buildings, pinpointing leaks and offering insights into potential improvements to optimize system performance.

Connecting with qualified local service providers ensures that duct leakage testing is carried out effectively and efficiently. Contractors in the area can provide comprehensive evaluations, often using specialized tools to detect leaks that are not visible to the naked eye. Property owners can expect clear explanations of test results and recommendations tailored to their specific needs. By exploring options from local pros, individuals can find the right professionals to help improve their HVAC system’s efficiency and indoor air quality.

Duct Leakage Testing Services

Learn how to evaluate duct systems to identify potential air loss issues before hiring a contractor.

Benefits of Comparing Local Contractors

This guide provides an overview of duct leakage testing to help visitors understand what to expect during the process. It assists in comparing and selecting local contractors who specialize in duct testing services. The information aims to prepare homeowners and property managers to communicate effectively with local service providers.